Our factory in Eschweiler/Germany boasts a comprehensive machine shop – the basis for our flexibility, and the guarantor of unwavering high standards of quality. The in-house production for precision bearings and linear technology is also used for the construction and manufacturing of complete customized solutions: Rodriguez develops and manufactures such Value Added Products (VAP) on the basis of entire technology- and system know-how as well as many years of experience.

Due to the in-house production and the short decision-making processes between sales, design and development Rodriguez is able to respond with much greater flexibility than their competitors. This is mainly because of the fact that all process steps can be done in-house – from the design via manufacturing and assembling.

In-house machinery

Rodriguez has an impressive machine park and a large in-house production depth for rotary and linear technology. The following examples show the range of the machine park:

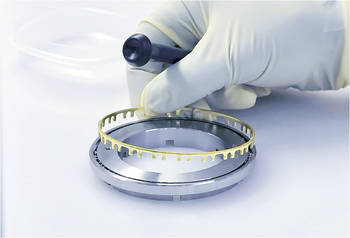

Measuring room

More precision for proofed quality

of linear technology and precision bearings

A separate measuring room allows Rodriguez to meet the highest demands and to check the required tolerances of precision bearings and linear technology in the µ-range. To improve their customer service, Rodriguez has invested in a new 3D measuring machine that can analyse bearings with large outer diameters of up to 1.500 mm. Furthermore, a machine for the measurement of contour and roughness of ball races is in use. Last but not least, an optical measuring system, equipment for checking roundness and hardness and a length measuring bench are used.

These devices allow the Eschweiler specialist to check the dimensional accuracy of machined shafts and ball screws, for example, and of milled parts such as bearing housings and shaft supports. Besides complex parts, also individual components can be inspected: Among other things, this is important for the value added products/customized solutions that Rodriguez designs and manufactures for their customers.

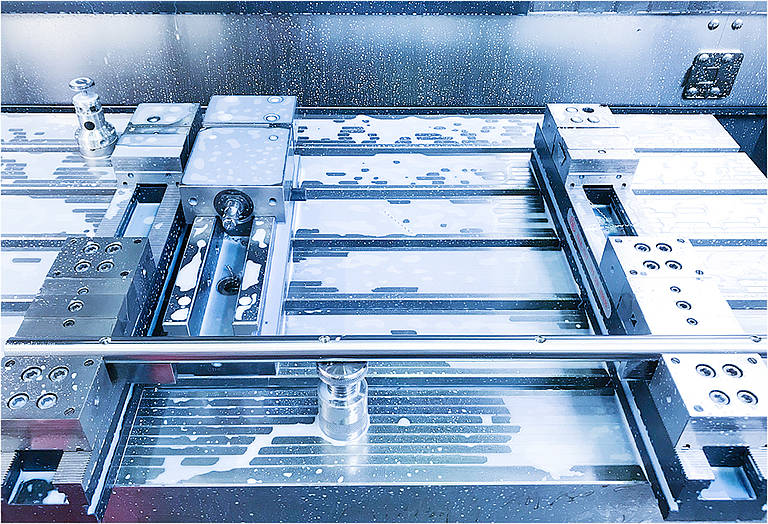

Clean room system

For more flexibility and individuality

Rodriguez continues to expand its production capacities in order to offer its customers even more flexibility and individuality. One example of this is a cleanroom, which is necessary for the assembling and production of semiconductor components.

Of course the production processes will be improved continuously. Innovative equipment and advanced tools ensure that the production systems always conform to the state of the art. Modern hybrid clamping tools enable a deformation-free clamping of bearing races.

Another high priority is the in-house quality inspection: The measuring room has recently been expanded to meet stringent requirements and to test the required tolerances. Rodriguez just invested in a new measuring machine which can analyse rolling bearings with large outer diameters of up to 1,500 mm.

End machining in linear technology

individual adaptations thanks to expertise in hard machining

Rodriguez also takes on end machining of linear technology products as part of the customer-specific adaptation of standard parts: this means that shafts, ball screws and trapezoidal screws can be modified in accordance with customer drawings. This guarantees top quality, since Rodriguez is a safe pair of hands as a specialist for hard turning when it comes to the machining of guide shafts. Our company owns special 5-axis CNC machines that are especially designed for hard machining. The background: soft materials can be machined by just any turning machine operator, but the machining of hardened surfaces is a case for the experts.

One example of the solutions implemented by Rodriguez is the complex machining of stainless steel shafts. The guide shafts are manufactured on behalf of a packaging machine manufacturer for the pharmaceutical industry. In this case, only the corrosion-free material stainless steel is suitable due to the extremely sensitive requirements within this industry. Thanks to the shafts machined by Rodriguez, this customer is able to ensure their assembly process is almost frictionless and comes with no loss of tolerance.

Stainless steel shafts are also in demand within the food industry: Rodriguez supplies both turned and milled versions to this industry. As a general principle, the end machining of linear products is especially popular with customers who need to guarantee extremely high accuracy when it comes to the final product. This also applies to the semiconductor industry, in which completely machined ball screws with increased shape and position tolerances are required. However, individually designed and produced components are also key within the packaging machine industry. Rodriguez implements complex machined guide shafts for customers in this industry.

Advantages of end machining performed by Rodriguez

- Customer-specific prefabrication of linear components

- Highest quality thanks to special CNC machines for hard machining

- Process optimisation thanks to outsourcing of end machining

- Taking special industry requirements into consideration

- Simplified assembly of machined components

- High precision for the final product